Activated carbon is not only used for water filtration but also finds extensive applications in air purification. Due to its exceptional adsorption capabilities, activated carbon is commonly used in air filters to remove harmful pollutants and odors from indoor environments. It effectively captures volatile organic compounds (VOCs), formaldehyde, benzene, and other toxic gases that can be emitted by furniture, carpets, cleaning products, and even building materials.

Moreover, activated carbon plays a crucial role in the pharmaceutical industry. It is utilized as an essential ingredient in medicinal drugs to remove impurities and toxins during the manufacturing process. The porous structure of activated carbon allows it to selectively adsorb unwanted substances while leaving behind the desired active ingredients intact.

In recent years, there has been a growing interest in using activated carbon for environmental remediation purposes. This versatile material has shown promising results in removing contaminants from soil and groundwater systems contaminated with industrial waste or hazardous chemicals. Its high surface area provides ample opportunities for chemical reactions and adsorption processes that help mitigate pollution levels. Furthermore, activated carbon has found applications in gas masks worn by firefighters and industrial workers exposed to toxic fumes or airborne particles. By trapping harmful substances present in smoke or chemical vapors, it acts as a protective barrier against respiratory ailments caused by inhalation of these hazardous agents.

The versatility of activated carbon extends beyond purification purposes; it also serves as an effective catalyst support material for various chemical reactions. Its large surface area facilitates better interaction between reactants and catalysts leading to enhanced reaction rates and improved product yields.

In terms of elemental composition, carbon accounts for more than 80%-90% of activated carbon, which is the primary reason for its hydrophobic nature. Apart from carbon, activated carbon also contains two types of impurities: chemically combined elements such as oxygen and hydrogen, which are retained in the carbon due to incomplete carbonization or chemically bonded to the surface during activation (e.g., oxidation occurs on the surface when activated by water vapor); The other type of impurity is ash, which constitutes the inorganic fraction of activated carbon and consists of various elements.

Activated carbon, a hydrophobic adsorbent derived from carbon-based materials through high-temperature carbonization and activation, possesses numerous micropores that contribute to its vast specific surface area. Consequently, it can effectively eliminate chroma and odor, as well as most secondary organic pollutants and some inorganic substances such as toxic heavy metals from water. The factors influencing activated carbon adsorption include the properties of the activated carbon itself, the characteristics and concentration of the adsorbed material, wastewater pH value, suspended solid content, and other system-related factors like contact time and operation mode. Therefore, activated carbon adsorption is regarded as an essential and efficient technology for advanced municipal sewage treatment.

Activated carbon is composed of tiny carbon particles with a large surface area, which contain even smaller capillary pores. These capillaries possess strong adsorption capacity due to the extensive surface area of the carbon particles, allowing them to effectively capture gases and impurities in the air.

The development of the activated carbon industry is preceded by the advancement of applications for activated carbon. The application of activated carbon is closely intertwined with scientific and technological progress as well as human life. Presently, a wide range of scientific fields incorporate the utilization of activated carbon in areas such as environmental protection, chemical industry, power generation, aerospace, etc. However, traditional applications primarily rely on its exceptional adsorption properties; hence it is crucial to further explore its usage in liquid and gas adsorption fields while simultaneously expanding its overall application.

1. Water purification

Biological activated carbon is a novel carbon material utilized for water purification, facilitating the proliferation of microorganisms within the pores of activated carbon and exhibiting aerobic biological activity. Extensive research and practical applications have demonstrated that in advanced drinking water treatment, biological activated carbon effectively eliminates chemical oxygen demand, turbidity, and chroma from water. This method has been widely adopted in various countries for drinking water treatment, sewage treatment, ozone treatment, and biological activated carbon processes. By synergistically harnessing both adsorption and degradation mechanisms, biological activated carbon serves as an exceptionally efficient approach to purify water and is expected to gain further popularity in the future.

2. Pharmaceutical industry

Activated carbon is widely used in the pharmaceutical industry, whether in biologics, chemical synthesis drugs, hormones, vitamins, injections, etc. It is necessary to use activated carbon as an adsorbent or catalyst carrier.

Blood purification is a prominent application of activated carbon as an adsorbent in the field of medicine, encompassing hemoperfusion and hemodialysis. To ensure biocompatibility, hydrophilic gels and polymer materials are employed to encapsulate the activated carbon, which directly interacts with blood cells. Spherical activated carbon is commonly utilized for adsorption-based removal of substances that contribute to kidney disorders, thereby mitigating toxin accumulation. Hemodialysis, also known as artificial kidney treatment, operates on the principle of membrane equilibrium wherein the patient’s blood traverses a thin film containing numerous micropores to selectively replenish essential substances while eliminating harmful ones. However, its efficacy in removing molecular substances from the bloodstream remains limited. Due to its exceptional adsorption performance and insolubility in dialysate or passage through dialysis membranes, activated carbon serves as an adsorbent for regenerating dialysate and aids in reducing its consumption.

1. Indoor air purification

Compared to outdoor air pollution, indoor environmental pollution poses a more direct threat to human health and is a significant contributor to allergies, asthma, immune disorders, and other related conditions. Various sources contribute to indoor environmental pollution, including building materials used in decoration, kitchen fumes, furniture emissions, and tobacco smoke. As people increasingly prioritize their home environment’s quality, the market demand for indoor air purification solutions is growing rapidly. Consequently, the utilization of efficient activated carbon air purification devices is becoming widely adopted. By adjusting the aperture size based on the type and molecular size of toxic gases present in a room, it becomes possible to effectively eliminate odors and eradicate indoor pollution.

2. Adsorbed organic waste gas

With the acceleration of the global trend towards industrialization, an increasing number of industries are utilizing various types of organic solvents. In order to prevent direct discharge of these solvents into the atmosphere during usage, it is necessary to recover or purify them. Activated carbon is widely employed for adsorption of organic solvents due to its cost-effectiveness and simplicity in operation. Through surface modification treatment, activated carbon can efficiently adsorb/desorb high concentrations of valuable organic gases without catalytically modifying the organic solvent on its surface, which would otherwise render recycled precious organic solvents unusable. For low concentration organic waste gas, it is recommended to employ activated carbon supported by metal catalysts in order to simultaneously catalyze degradation of the organic solvent into CO2 and H2O during the adsorption process; currently this method can achieve purification down to a concentration level as low as 10-6. As governments worldwide increasingly prioritize environmental protection and resource recycling, there will be a growing demand for comprehensive systems utilizing activated carbon for recovery of all types of organic solvents.

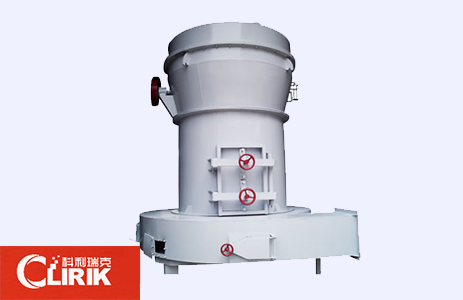

High Pressure Grinding Mill

Capacity:1-50 t/h

Feed Size:35 mm

Powder Fineness:50-400 mesh

YGM high pressure mill, also known as high pressure hanging roller mill or pendulum mill, is an upgraded version of Raymond mill. It uses a closed cycle for high precision milling, which improves the output and production efficiency to a certain extent. It can replace ball mills as highly efficient milling equipment.

1. The wide range of finished particle sizes allows for a particle size of 0.300mm (50 mesh) for the finished product, while the fine powder typically has a particle size of 0.0374mm (400 mesh).

2. Good environmental protection effect is achieved through the roller mill’s adoption of superimposed multistage seals, which provide excellent sealing performance and dust removal effects that fully comply with national dust emission standards.

3. The roller mill achieves high year-on-year output by increasing output by 20-30% compared to other mills under similar dynamic conditions, and by applying grinding pressure on the material through the YGM high pressure mill roller, which increases by 800-1200kg due to the action of the high pressure spring.

4. The unique structural design includes a pressure device in the form of a high pressure spring, which increases roller pressure by 800-1200kg and boosts output by 20-30%.

Clirik is a reputable manufacturer of mining machinery and equipment, renowned for their global popularity. If you have any interest in our top-notch equipment, please feel free to contact us using the information provided on this page. Moreover, we boast a team of highly skilled engineers and technicians who are capable of tailoring machinery and equipment to meet your specific requirements, ensuring that they perfectly suit your needs. We eagerly await your call!