Capacity:20~200 t/h

Max Feeding Size:25 mm

Finished Size:40~200 mesh

Range of application: Barite, quartz, feldspar, mica, calcite, talc, apatite, gypsum, fluorite, limestone, dolomite, diatomite, ceramic soil, clay, marble, granite, fly ash, kaolin, calcium carbonate, slag, bauxite, glass, etc.

Ball mill is the key equipment for grinding after crushing, widely used in cement, silicate, new building materials, refractories, fertilizers, ferrous metals, non-ferrous metals and glass ceramics manufacturing, can be used for a variety of ores and other abrasive materials dry and wet grinding.

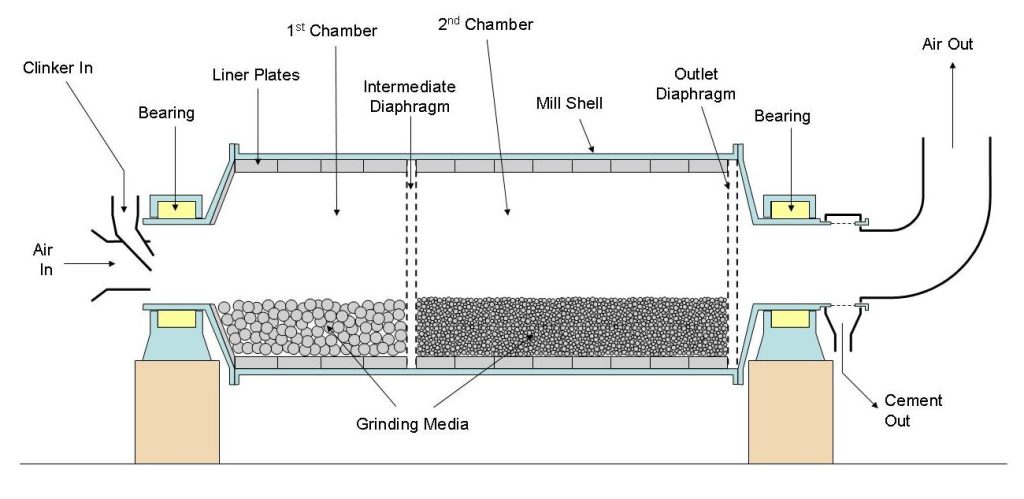

The ball mill is composed of feeding part, discharging part, rotating part, transmission part (reducer, small transmission gear, motor, electric control) and other main parts. The hollow shaft is made of steel casting, the inner lining can be disassembled, the rotary gear is made of casting hobbing, and the cylinder body is inlaid with wear-resistant lining plate, which has good wear resistance. The machine runs smoothly and works reliably.

Ball mill is composed of a horizontal cylinder, inlet and outlet hollow shaft and grinding parts, the cylinder is a long cylinder, the cylinder is equipped with a grinding body, the cylinder is made of steel plate, there is a steel lining plate and the cylinder is fixed, the grinding body is generally a steel ball, and is loaded into the cylinder according to different diameters and a certain proportion, the grinding body can also be used steel section. According to the particle size of the grinding material is selected, the material is loaded into the cylinder by the hollow shaft of the feed end of the ball mill. When the ball mill cylinder rotates, the grinding body is attached to the lining plate of the cylinder due to the action of inertia and centrifugal force, and the action of friction force, so that it is taken away by the cylinder. When it is brought to a certain height, it is thrown off due to its own gravity. The falling abrasive body acts like a projectile and shatters the material inside the cylinder.

1.Use large diameter double row aligning roller bearings to reduce friction and reduce energy consumption by 20-30%.

2.End cover structure, large diameter import and export, processing capacity increased by 15-20%.

3.Simple structure, split installation.

4.No inertia impact, the equipment runs smoothly, reduces the mill downtime, and increases the efficiency by 15-25%.

| Model | Rotary speed (r/min) | weight(t) | Input size (mm) | Discharge size (mm) | Capacity (t/h) | Motor power (kw) | Weight (t) |

|---|---|---|---|---|---|---|---|

| Ф900*1800 | 39 | 1.5 | ≤20 | 0.075-0.89 | 0.8-2 | 18.5 | 4.6 |

| Ф900*1800 | 39 | 2.7 | ≤20 | 0.075-0.89 | 1-4 | 22 | 5.6 |

| Ф1200*3000 | 36 | 3.5 | ≤25 | 0.074-0.4 | 1.6-5 | 37 | 12.8 |

| Ф1200*4500 | 32 | 5 | ≤25 | 0.074-0.4 | 1.6-5.8 | 55 | 13.8 |

| Ф1500*3000 | 27 | 7.5 | ≤25 | 0.074-0.4 | 2-5 | 75 | 15.6 |

| Ф1500*5700 | 28 | 12 | ≤25 | 0.074-0.4 | 3.5-6 | 130 | 24.7 |

| Ф1830*3000 | 25 | 11 | ≤25 | 0.074-0.4 | 4-10 | 130 | 28 |

| Ф1830*6400 | 24 | 21 | ≤25 | 0.074-0.4 | 7-16 | 210 | 34 |

| Ф1830*7000 | 24 | 23 | ≤25 | 0.074-0.4 | 8-18 | 245 | 36 |

| Ф2100*3600 | 23 | 19 | ≤25 | 0.074-0.4 | 10-36 | 210 | 46 |

| Ф2200*4500 | 21 | 27 | ≤25 | 0.074-0.4 | 12-23 | 280 | 48.5 |

| Ф2200*6500 | 21 | 35 | ≤25 | 0.074-0.4 | 14-46 | 380 | 52.8 |

| Ф2200*7000 | 21 | 35 | ≤25 | 0.074-0.4 | 15-28 | 380 | 54 |

| Ф2200*7500 | 21 | 35 | ≤25 | 0.074-0.4 | 15-30 | 380 | 56 |

| Ф2400*4500 | 21 | 30 | ≤25 | 0.074-0.4 | 18-45 | 320 | 65 |

| Ф2400*8000 | 20 | 36 | ≤25 | 0.074-0.4 | 20-48 | 410 | 81 |

| Ф2700*3600 | 21 | 39 | ≤25 | 0.074-0.4 | 19-75 | 400 | 83 |

| Ф2700*4000 | 20 | 40 | ≤25 | 0.074-0.4 | 20-78 | 400 | 85 |

| Ф2700*4500 | 20 | 48 | ≤25 | 0.074-0.4 | 22-85 | 430 | 89 |

| Ф3200*4500 | 18 | 65 | ≤25 | 0.074-0.4 | 29-140 | 800 | 137 |

| Ф3200*5400 | 18 | 81.6 | ≤25 | 0.074-0.4 | 30-180 | 800-1000 | 146 |

| Ф3600*4500 | 17 | 88 | ≤25 | 0.074-0.4 | 35-210 | 1000 | 190 |

| Ф3600*6000 | 17 | 117 | ≤25 | 0.074-0.4 | 38-240 | 1250-1500 | 220 |

| Ф3600*8500 | 17 | 144 | ≤25 | 0.074-0.4 | 45-260 | 1800 | 260 |