1.Introduce to Ultrafine vertical roller mill

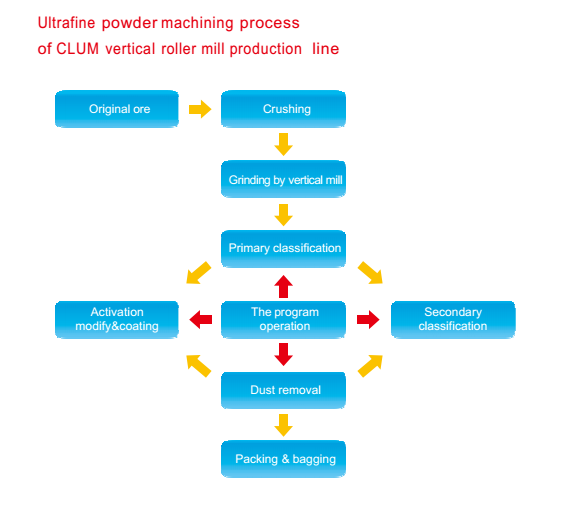

2.Working Principle

3.Production Specification

Capacity:0.2~45 t/h

Feeding size:30 mm

Finished powder:150~3000 mesh

Product features: Intelligent, high production capacity, low vibration noise, wide range of application, Mohs hardness below 9 materials can be ground.

CLUM series ultrafine vertical roller mill is independently designed by Clirik on the basis of years of experience in grinding mill production.

CLUM series ultrafine vertical roller mil adopts the latest Taiwan grinding roller technology and German powder separating technology. The ultrafine vertical grinding mill integrating ultrafine powder grinding, grading and transporting has become a great choice in the ultrafine powder grinding industry.

Step 1 Feed

The material is fed through the screw feeder into the center of the grinding plate of the CLUM series ultra-fine vertical roller mill.

Step 2 Grind

The motor of the main mill drives the reducer, and the reducer drives the grinding disc to rotate. This rotation creates a centrifugal force that moves the material towards the edge of the mill. When the material passes through the grinding zone between the roller and the grinding plate, the bulk material is directly broken by the pressure of the roller,the broken materials become finer as they push against each other.

Step 3 Selection of airflow and powder

After crushing, the broken material continues to move towards the edge of the grinding plate. They are carried away by the air stream into the powder selector. Inside the powder selector, the blades separate coarse particles that do not meet the required fineness criteria. These coarse particles fall back onto the grinding plate for further grinding. Powders that meet fineness requirements enter the powder collector as finished products.

Step 4 Remove debris

If there are impurities such as iron blocks in the material, when they move towards the edge of the mill plate, their heavier weight causes them to fall into the lower chamber of the mill. A scraper mounted on the bottom of the grinding plate removes these impurities and feeds them into the discharge port. Finally, the impurities are discharged from the mill.

| Model | CLUM1425 | CLUM1632 | CLUM1736 |

|---|---|---|---|

| Working Diameters (mm) | 1400 | 1600 | 1700 |

| Number of rollers (pieces) | 3 | 3 | 3 |

| Number of classifier (pieces) | 5 | 7 | 7 |

| Power of classifier (KW) | 5×15 | 7×15 | 7×15~18.5 |

| Main unit power (KW) | 250 | 315 | 355 |

| Blower power (KW) | 200 | 250 | 315 |

| Feed size (mm) | <10mm | <10mm | <10mm |

| Moisture of feeding mateial | <3% | <3% | <3% |

| Less than 2μm=34% output(t/h) | 11~14 | 13~17 | 15~19 |

| Less than 2μm=46% output(t/h) | 7~8 | 9~10 | 11~12 |

| Less than 2μm=60% output(t/h) | 3~4 | / | / |

Clirik is a professional manufacturer of mining machinery and equipment, the production of machinery and equipment in the world are very popular, if you are interested in our equipment, please contact us through the contact information on the page, we also have professional engineering and technical personnel for you to customize machinery and equipment, to meet your requirements, to create suitable for your use of equipment, welcome your call!