1.Applications of calcium carbonate

2.Production line process

3.The Advantage Of Raymond Mill Production Line

Capacity:0.2~50 t/h

Max feeding size:35 mm

Finished powder:80~325 mesh

250 mesh to 300 mesh: used as raw materials for plastic factories, rubber factories, coating factories, waterproof materials factories and interior and exterior coatings. The whiteness is above 85 degrees.

Calcium carbonate within 200 mesh can be used for various feed additives with calcium content higher than 55.6 and no harmful ingredients.

These fineness requirements Raymond mill can be extremely well completed.

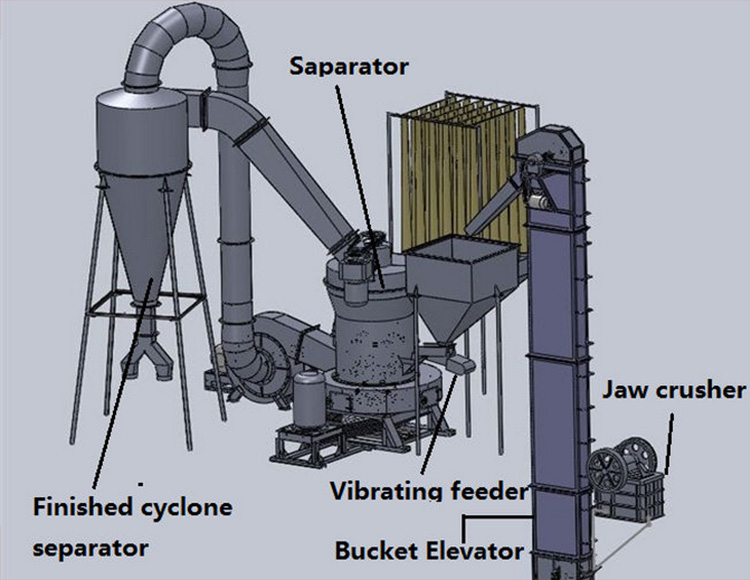

Calcium carbonate in other industries before the application, generally need to be made into powder, the production process is large lump raw materials after crushing jaw crusher, under the action of vibrating screen machine on the finished product classification, after the belt conveyor will be sifted after the material uniform and continuous to Raymond mill grinding, under the action of the blower separation, after the powder discharge is the finished product.

(1) The overall floor area of the production line is small, the investment cost is low, the entire production line operation automation degree is high, the production workshop can basically achieve unmanned operation, save cost expenditure.

(2) A wide range of equipment application materials, the production line can also process other materials, expand the scope of application, a wide range of granularity processing, can produce a variety of specifications of finished products, to meet the different needs of users, a multi-purpose machine, to create higher economic benefits.

(3) Low energy consumption in the production process, good grinding effect, sifting rate of up to 99%.The dust in the production process is small, and the dust removal device is equipped to effectively reduce the amount of dust in the production process and achieve dust-free operation. The air flow in the cyclone separator can be recycled, reducing system losses.

Clirik is a professional manufacturer of mining machinery and equipment, the production of machinery and equipment in the world are very popular, if you are interested in our equipment, please contact us through the contact information on the page, we also have professional engineering and technical personnel for you to customize machinery and equipment, to meet your requirements, to create suitable for your use of equipment, welcome your call!